EASYCAD.

Designing with EASYCAD

SOFTWARE

The all-in-one tool

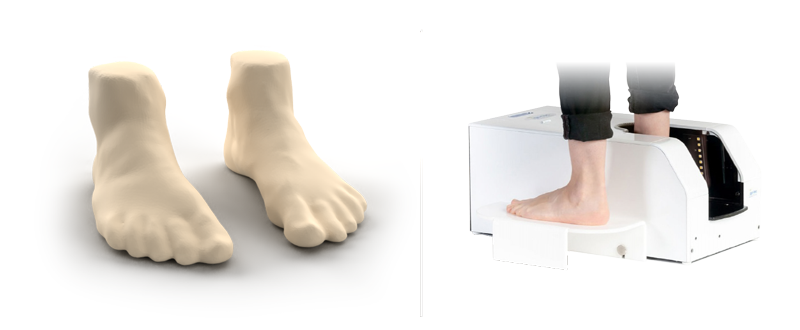

Measuring systems

billing systems

YOUR ADVANTAGES

BASIC MODULES

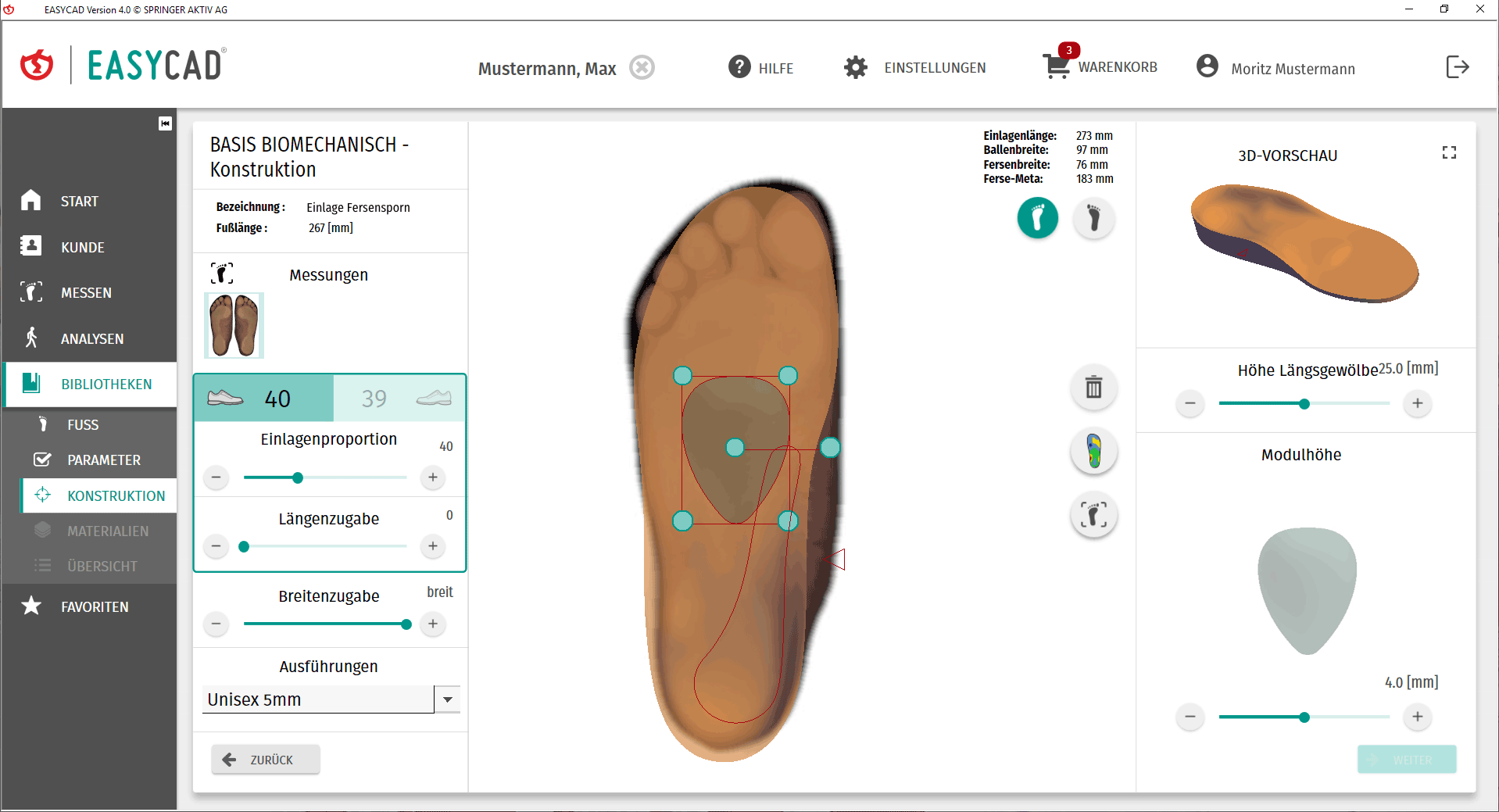

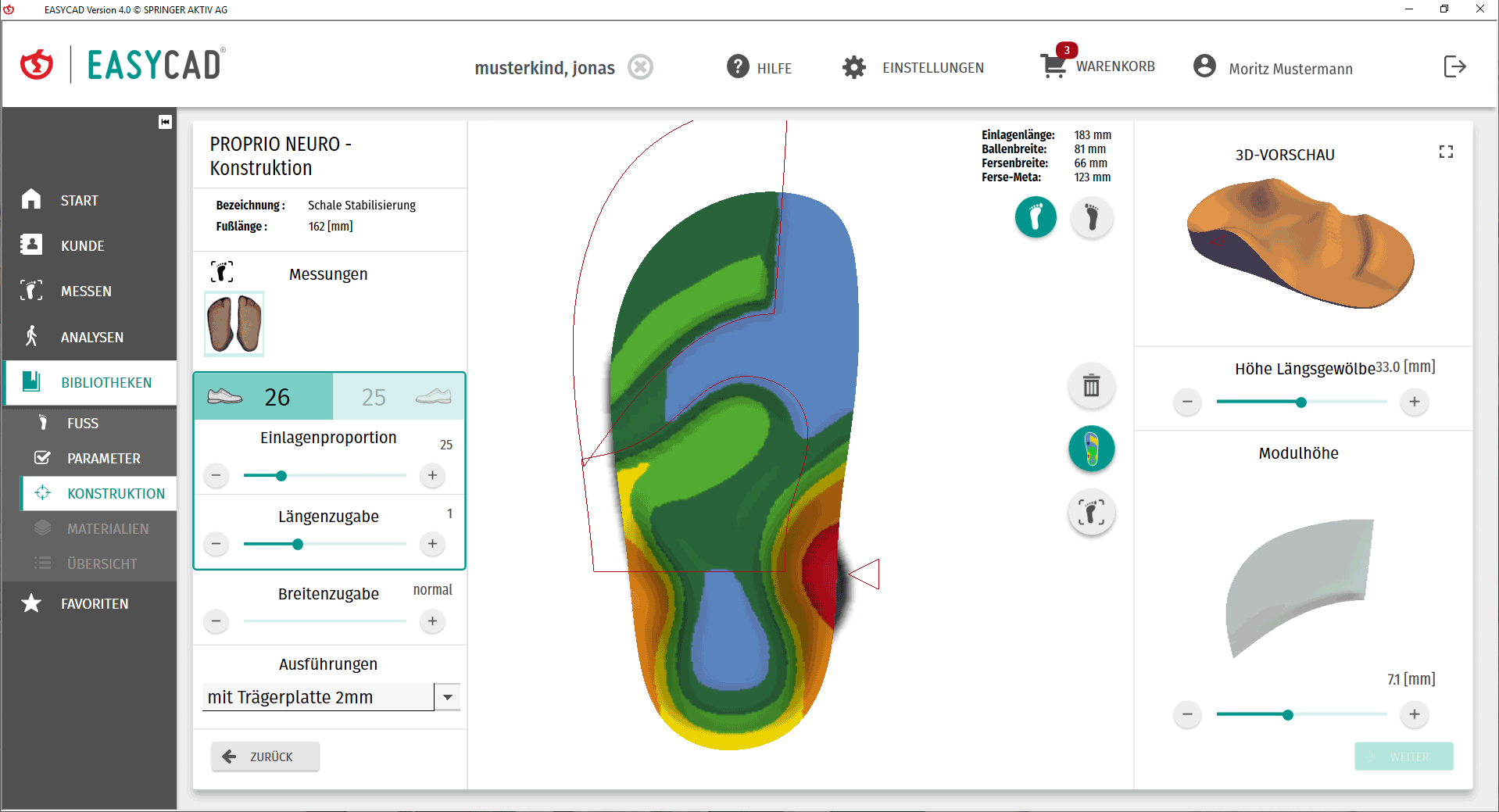

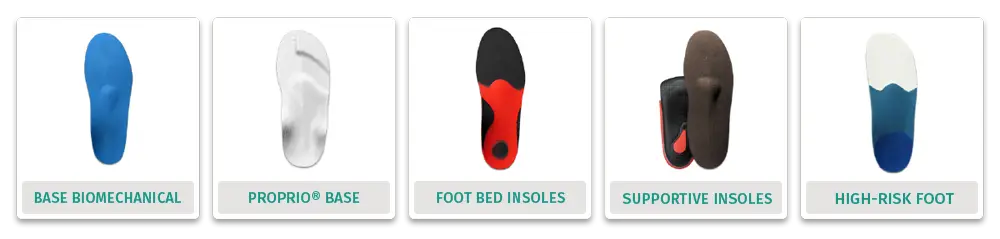

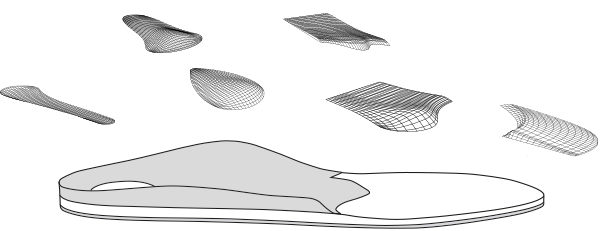

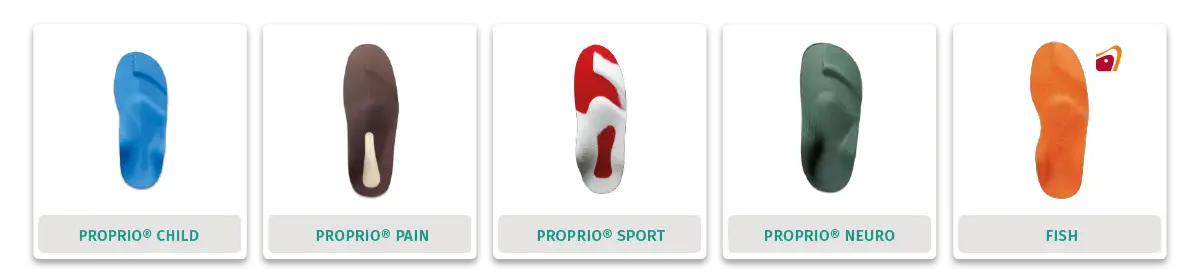

Biomechanical or sensorimotor - you decide

Realise your philosophy.

Use our indication-specific

Model libraries

DAF digital

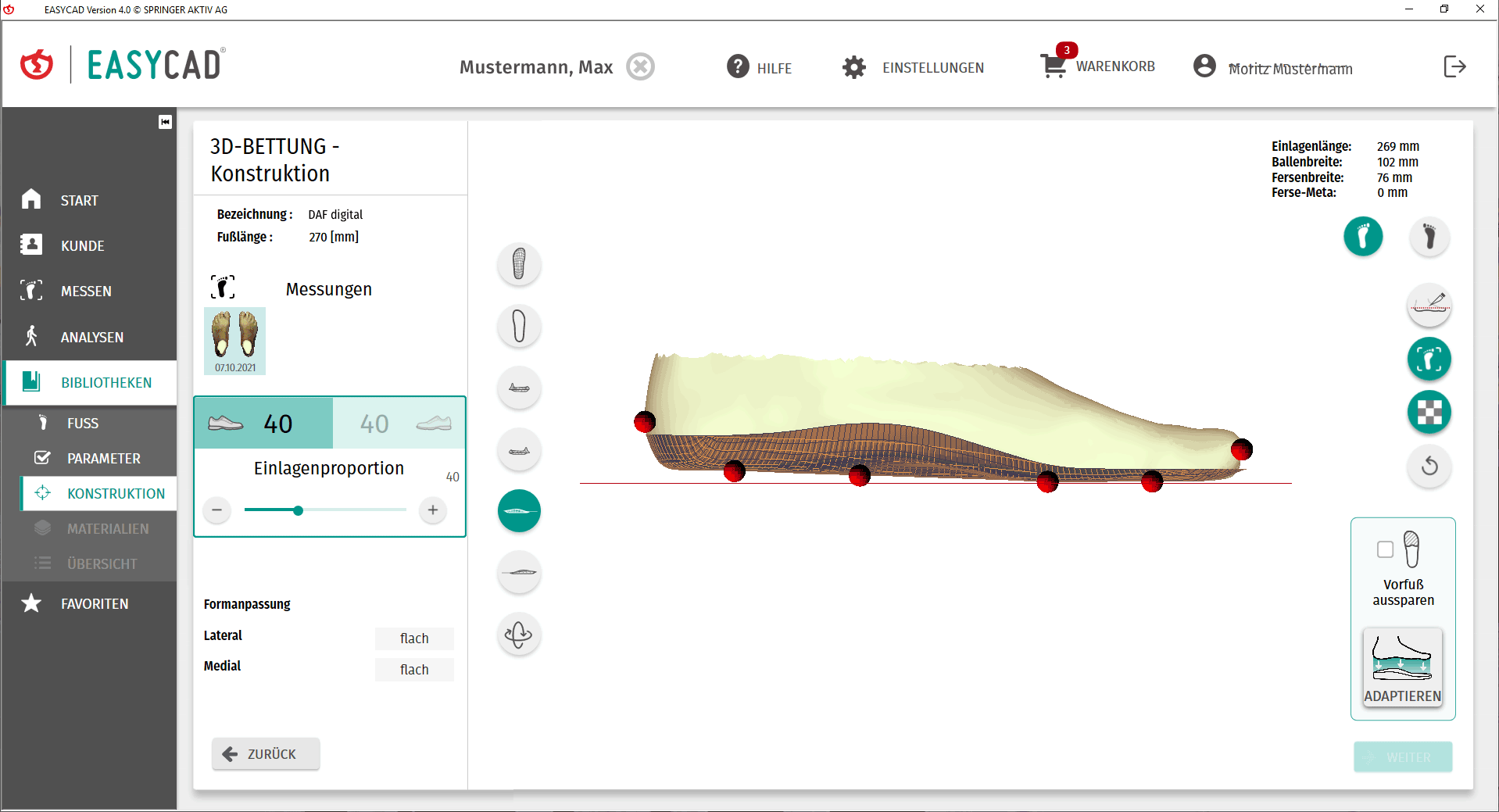

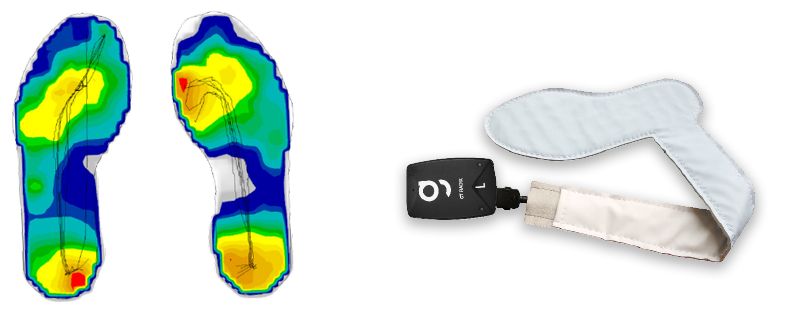

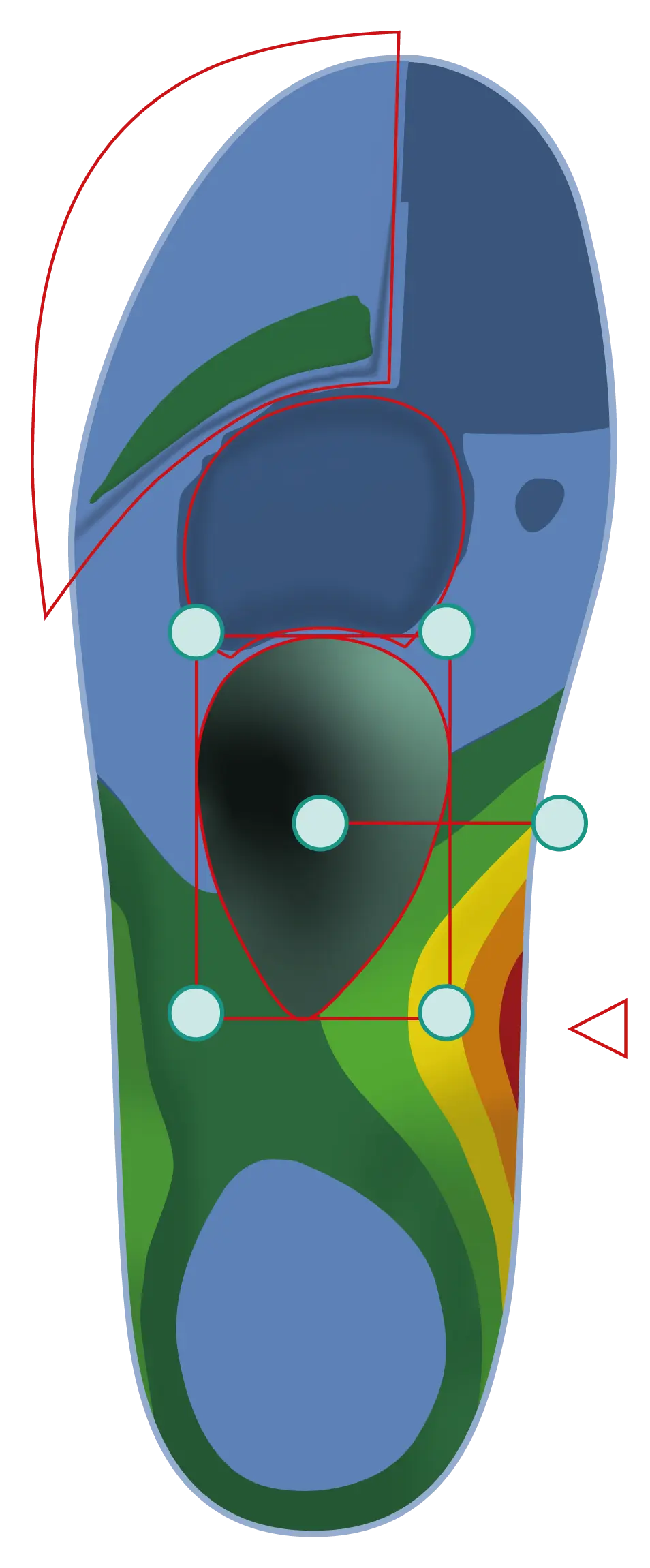

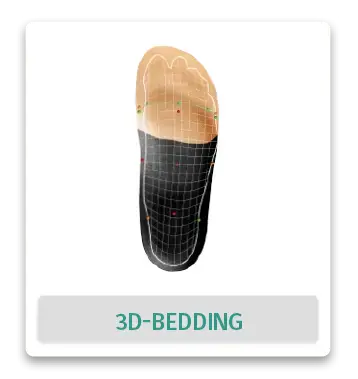

EASYCAD 3D bedding - The advanced tool for diabetes-adapted footbeds

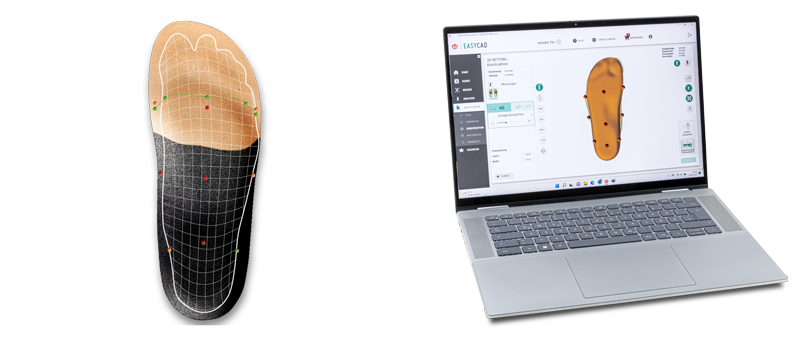

Easy customisation with the 3D bedding tool

The 3D bedding tool makes it easy for you to adapt the foot scan to the insole. This allows you to customise the insole, ensure optimum heel guidance and adapt it to the material thickness of 6-14 mm.

The innovative "3D bedding" library in the PG31

The new PG31 officially enables new manufacturing processes for the production of diabetes-adapted footbeds (DAF) for the first time. Easycad, the market-leading CAD software from SPRINGER for the design and production of individual insoles, has been expanded to include the “3D bedding” library. This digital platform is the ideal tool for the digital production of bedding insoles.

Perfect fit in just a few steps

In just a few steps you can get your finished footbeds by adapting a 3D foot scan. These are characterized by their high heel cups and ensure excellent rearfoot guidance. The heel is positioned optimally in the shoe, which means the foot does not “float”. This is a crucial criterion, especially for polyneuropathy patients with sensory disorders, in order to perform safely.

Flexible customisation possible

The material thickness of the insoles is extremely flexible and can be customised in the range of 6-14 mm. This means that the insoles can be made narrower in the rearfoot area for improved support in the shoe. At the same time, however, the prescribed minimum material thickness of 8 mm can be maintained in the case of a healed ulcer.

During the design process, you can choose from the insole moulds of all common shoe manufacturers to ensure a perfect fit. The generated CAD files can either be milled or soon produced using 3D printing - either in the central service centre or directly in-house. These versatile options offer you maximum flexibility in the production of your insoles.

Are you ready to get started?

Try EASYCAD for free for 3 months

FAQ

The following system requirements are necessary:

- Operating systems:Windows 10/11 (64-bit)

- Minimum requirements:Processor: Intel I3 5th generation, RAM: 4 GB

- Recommended: Processor Intel I5 5th generation, RAM: 8 GB, hard drive storage: SSD

- Screen resolution:1920 x 1080 Full HD

- Only compatible with GpManager 7

Download the Demo version or request the installation package on a USB stick.

To install and activate individual libraries, please contact Springer Aktiv AG customer support and make an appointment:

- Telephone: +49 (0)30 49 00 03 - 0, e-mail:

- Important: The programme can only be activated via SPRINGER AKTIV AG!