Manufacturing technology.

Choose independence and efficiency in your orthopedic workshop through in-house production. With Springer you not only rely on innovative technologies such as milling and 3D printing, but also on the advantages of in-house production.

Your advantages

Independent of supply chains

In-house production means you are independent of supply chains and external suppliers. This autonomy allows you to react flexibly to your customers' needs and control your production yourself. Say goodbye to external dependencies and stay in control of your manufacturing processes.

Expertise for your company

Use the manufacturing know-how in your own company and rely on your expertise. At Springer, you not only get state-of-the-art production technology, but also the knowledge and experience of an innovator in orthopaedic (shoe) technology. Our consistent development of new technologies is reflected in the innovative strength that goes into every product.

Increase your efficiency

In-house production not only offers independence, but also cost-effective production. Reduce expenses, increase efficiency and stay in control of your budget. Decide for full control and management of your manufacturing processes in the future.

Milling machine

The built-in vacuum table allows the milling machine to be loaded with material without additional gluing. The suction preparation allows the machine to be operated either on a central suction system or a separate industrial vacuum cleaner. Equipped with a quiet and robust spindle motor with carbon brushes, the “GT Rocky” is the optimal solution for independent milling in your workshop.

Use the full range of Springer CAD know-how by using Easycad as design software to control your own "GT Rocky" milling machine. By using Easycad you gain access to comprehensive model libraries for quick and efficient construction of your dimensional insoles. Thanks to the dongle license milling, you can create your milling files directly on your own machine. This seamless integration of Easycad not only optimizes your design processes, but also enables your ideas to be efficiently translated into high-quality insoles.

Contact 3D printing

Do you have further questions?

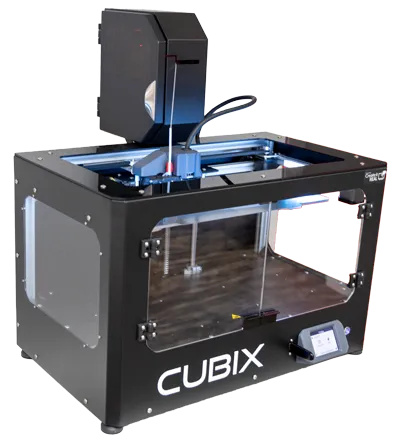

3D printer

3D printing is not only a pioneering manufacturing technology, but also an environmentally friendly solution. The materials used are fully recyclable and therefore contribute to sustainable production.

The production process is optimised by transferring the print data directly from the Easycad design program to the printer. The precise print quality ensures that the insole is ready for use immediately after printing and only needs to be covered.

Invest in the future of your orthopaedic business and benefit from the flexibility and efficiency of the GP Mike 3D insole printer. Show your customers that you have your finger on the pulse and rely on sustainable, innovative technologies.