Software.

Precise manufacturing and digital processes.

With our EASYCAD software, you can optimise your orthopaedic insole production through digital and efficient processes. The software is easy to use, enables fast design with automated processes and ensures maximum precision and individuality for every insole. The software can also be seamlessly integrated into 3D printing and milling technology.

With the EASYCAD software, you save valuable time and offer your customers perfectly customised inserts.

2 libraries

for 3D printing.

EASYCAD has 2 libraries for producing 3D-printed inserts:

Bedding insoles

This library for the treatment of everyday complaints is included in the basic installation.

3D bedding / DAF

To create diabetes-adapted foot supports (DAF), you need this special library in addition to the basic installation.

4 steps to a customised 3D printed insole

Scan the footprint and import the data directly into the EASYCAD software. Data can also be imported from any scanner in .STL or .OBJ format.

Customise the insert in the EASYCAD software with our libraries and the Point Cloud for different degrees of hardness to meet your customer's exact requirements.

Send the finished file directly to your printer or to the Springer 3D printing service, which will produce the inlay for you with the highest precision.

The customised insole is delivered within 48 hours, is ready for immediate use and can be fine-tuned if necessary.

DAF digitally 3D-printed

PG 31 compliant

Digital process chain from a one-stop solution provider

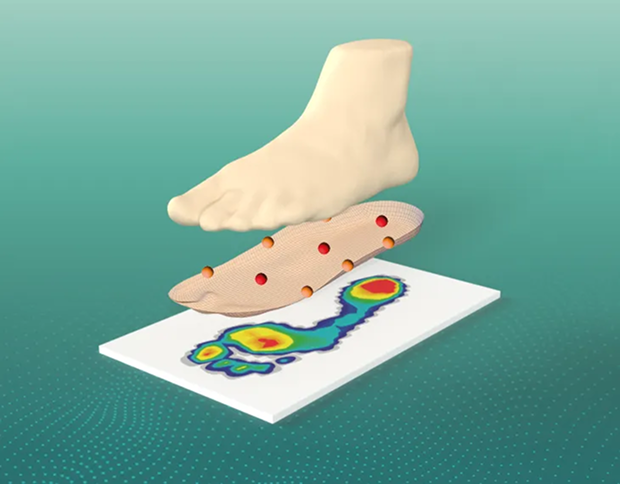

Use EASYCAD as a tool to map the complete fitting process for diabetes-adapted foot supports (DAF).

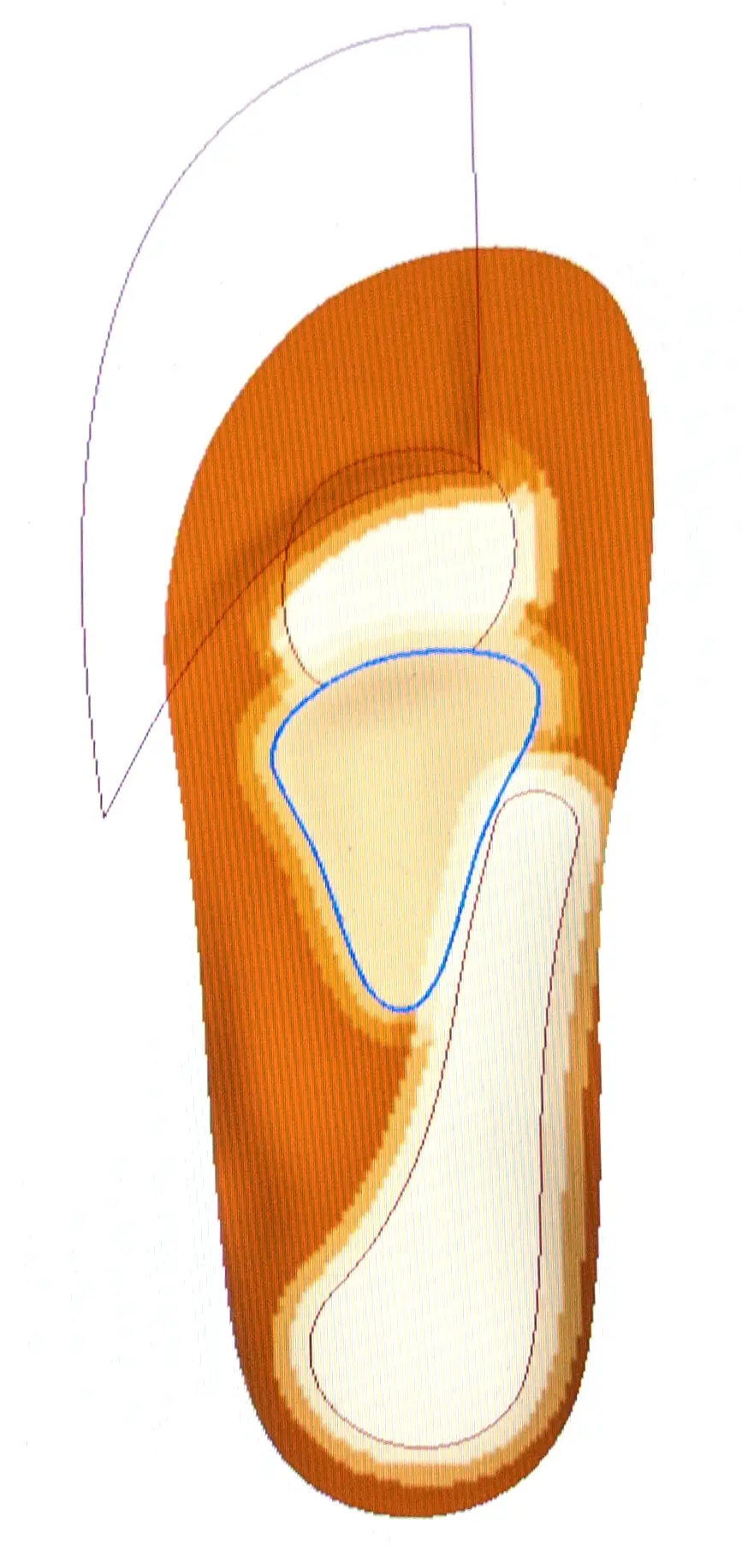

Pedography

Pressure distribution measurement for identification of ROI (region of interest) and documentation of pressure relief, e.g. with the mobile pressure gauge. Inner shoe measuring system GP Radix.

3D scan

as a design basis, e.g. with the 3D full-foot scanner GP Laser Scan 3D.

Adaptation

Use EASYCAD to transfer the scanned footprint to the surface of the insole. This ensures an optimum fit and stable return.

Construction

Provide functional relief or correction in the footbed.

Manufacturing

on your own printer or in the central printing service.

Documentation

EASYCAD erstellt automatisch ohne extra Aufwand Einlagen-Protokolle, die Sie für Kostenträger benötigen.

Benefits

with EASYCAD

Efficiency & time saving

EASYCAD allows you to create orthopaedic foot orthoses faster and more precisely. Automated processes and digital modelling reduce manual effort. This allows you to save valuable time and process more orders in less time.

Future technology

EASYCAD combines digital design with modern 3D printing and innovative manufacturing techniques. The software opens up new opportunities for young orthopaedic footwear technicians in particular to combine their profession with the latest technology and develop future-proof solutions.

Precision & individualisation

Every customer has different needs - with EASYCAD you can fit insoles with millimetre precision. Biomechanical libraries and intelligent customisation functions ensure optimum wearing comfort for your customers, especially those with demanding diabetic feet.