9. October 2025

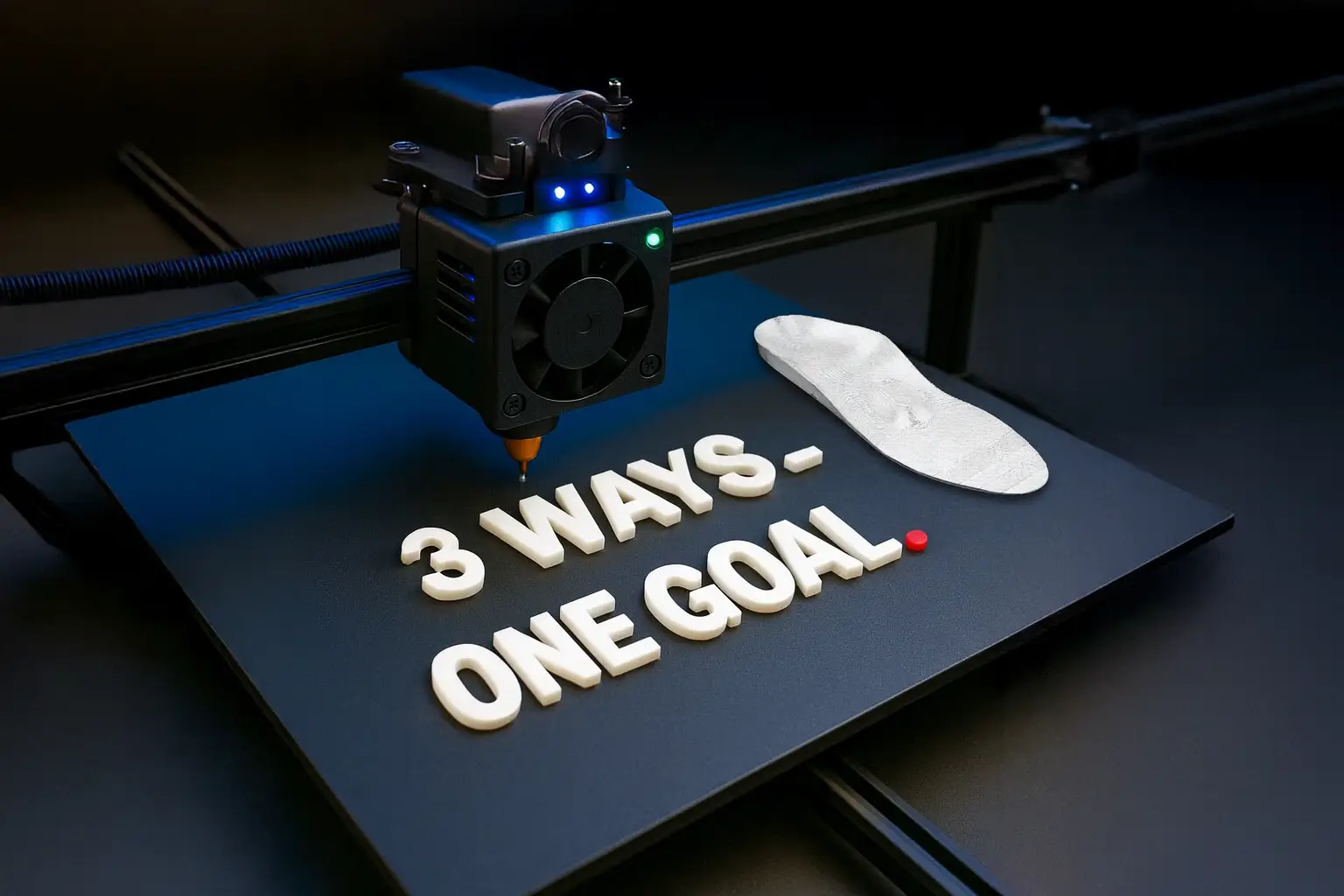

3 ways – one goal.

The launch of 3D-printed insoles

The future is tangible

and begins now.

TPU insoles: high-tech meets maximum comfort

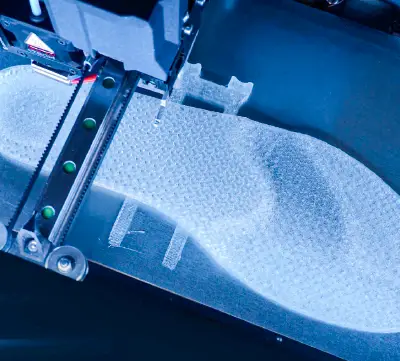

3D-printed insoles made of thermoplastic polyurethane (TPU) are not only a technological milestone, they also feel exactly like one: light, precise, elastic – and at the same time stable and skin-friendly.

Thanks to state-of-the-art manufacturing technology, insoles are created with smooth transitions, an anatomically perfect fit and a level of comfort that delights patients.

The cushioning is perfectly adapted to pressure points under the foot and provides pain relief all the way up to the head. And thanks to its lasting elasticity, customers and patients will enjoy this unique product for a long time and will recommend you and your company to others.

Those who position themselves regionally as providers of modern 3D care today will secure decision-making authority when it comes to prescriptions tomorrow.

Thinking strategically ahead and shaping the future

3D-printed insoles are not a short-term trend, but offer real added value for your patients – medically, functionally and ecologically.

At the same time, the new technology reduces the workload in your own workshop: the insoles come out of the printer ready to be inserted into the shoe, regardless of the available manpower.

→ Now is the right time to get started with a suitable concept – regardless of whether you are aiming for a quick start or complete customisation.

3D printing that strengthens your workshop – without fraying your nerves.

Customised insoles that are economical, quick and without complicated technology – that's exactly what Springer offers you with its entry into 3D printing.

Whether you want to get started right away or retain full control over the structure and design, we will provide you with the right solution – tailored to your processes, your team and your patients.

→ The quick and easy introduction:

For anyone who wants to get started pragmatically. Get started right away at the POS – without any effort or risk. Ideal for businesses that don't want to waste time or change their processes. More info →

✔ Centralised production by Springer

(service within 48h)

→ More influence, minimal effort – easy to configure, no paperwork:

For anyone who wants to customise but doesn't want to use CAD. Use the digital form to specify the shape, height and soft bedding – quickly, clearly structured and without time-consuming screen work. For everyone who prefers to be in the workshop rather than sitting in front of a computer. More info →

✔ Centralised production by Springer

(service within 48h)

→ Full customisation – design directly on the scan or pedography:

For digitally savvy technicians who want 100% control but don't need to be CAD professionals. A fully customised insole in just a few clicks: Design the shape, function and material flow to fit perfectly. Ideal for businesses that want to integrate 3D treatments professionally and digitally – with maximum flexibility and minimum effort.

More info →

✔ Centralised production by Springer

(service within 48h)

✔ In-house production

(own printer)

We have compiled all the information for you in a brochure that you can download.