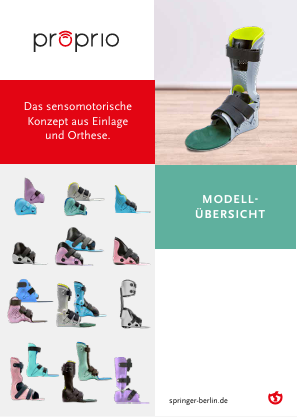

Paediatric orthoses proprio AFO

The concept of a 3D-printed orthoses and sensorimotor insoles

Advantages

that speak for themselves.

The Proprio AFO is a standardised paediatric orthosis that is manufactured using a precise 3D printing process. It impresses with its consistently high quality and saves you valuable time.

- No on-site production necessary

The orthosis is manufactured entirely by us using the 3D printing process. This saves you time and eliminates the need for additional specialised staff or complex production processes in your workshop. - MDR-compliant and yet customised

The proprio AFO fulfils all MDR requirements. At the same time, the end product remains a customised product from your company. - Large variety of models for maximum depth of care

Thanks to the wide range of models, you will find the right solution for every indication. The orthosis can be optimally customised to the needs of the respective child - Simple digital workflow without technical restrictions

The orthosis is easily created using our configurator. The entire process is reproducible and works with the scanning technology you already use. - Unique combination with integrated sensorimotor insole

The proprio AFO combines the paediatric orthosis with the sensorimotor foot orthosis to create a sophisticated overall concept. The insole is taken into account directly in the configuration process and is perfectly matched to the orthosis. - Risk-free in use

Thanks to our MDR-compliant processes, you receive a fit guarantee within the first three fittings. We also assume liability for you.

State-of-the-art technology

meets traditional craftsmanship

proprio orthoses are manufactured in the central printing service using the HP Multifusion process, right down to the intelligent fasteners. Unlike the SLS process used by other providers, this makes the orthosis less brittle and less prone to breakage.

proprio AFOs are characterised by flowing material transitions that create a delicate product. Only the areas where patients need stability are printed thicker.

The minimal weight of the orthoses will inspire you - and support your little patients in opening up new areas of movement. As the most innovative 3D-printed orthosis on the market verändert proprio AFO die Welt der Orthesenversorgung nachhaltig.

Properties

Edge padding

3D-printed fasteners

Pleasant wearing climate

Different joint types

3D-printed tabs

Variable material thicknesses

proprio SOLE

Easy getting started

into a pioneering technology

You can learn these in our free online course .

Register here.

For example, use your iPhone with the SPRINGER Scan App.

(The mirror attachment for the iPhone will also be available soon).

Our experts

Master orthopaedic technician

Master orthopaedic shoemaker

Master orthopaedic technician

Master orthopaedic shoemaker