Learn how you can use innovative 3D printing technology to produce precise, customized orthopedic insoles yourself.

We offer flexible solutions to efficiently and cost-effectively establish 3D-printed insoles in your company—depending on the size of your company and your individual requirements.

Benefits

your customers will love.

Sustainable

CUBIX insoles are produced locally or via a central 3D printing service. This process generates no unnecessary waste and makes you independent of long supply chains.

The insoles are made from TPU, which can be cleaned, melted down, and reprocessed into new filament for 3D printing. TPU, welches gereinigt, eingeschmolzen und zu neuem Filament für den 3D-Druck verarbeitet werden kann.

Customizable

Einzigartige, fließende Shorehärten von 20 - 80° Shore A garantieren eine komfortable und individuelle Anpassung auf die Patientenbedürfnisse.

Breathable

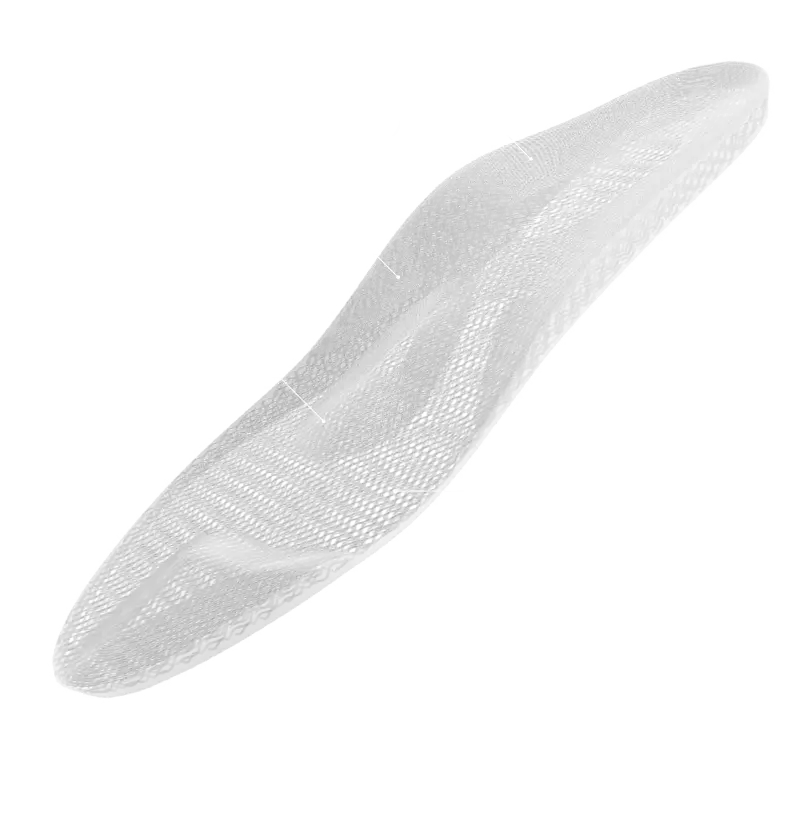

Visually, our insoles resemble a knitted pattern, they are open-pored and air-permeable and thus ensure better air circulation and a fresh foot climate.

What's the best way to start?

Advantages:

- Order inserts such as blanks directly from the web shop

- 4 preconfigured models

- Sneaker/casual insole mold

- Heel cup with 3 mm forefoot thickness

- Black TPU, insole body 35° Shore A, soft pads 25° Shore A

Models

ZF 3D-01

flat foot – Longitudinal arch support, drop pad

ZF 3D-02

flat foot – Longitudinal arch support, drop pad, heel spur soft padding

ZF 3D-03

Pes planovalgus et abductus – Longitudinal arch support, drop pad, forefoot cushioning (metatarsal head II–III)

ZF 3D-04

Pes planovalgus et abductus – Longitudinal arch support, drop pad, heel spur soft bedding, forefoot cushioning (metatarsal head II–III)

→ More influence, minimal effort – easy to configure, no paperwork:

For anyone who wants to customise but doesn't want to use CAD. Use the digital form to specify the shape, height and soft bedding – quickly, clearly structured and without time-consuming screen work. For everyone who prefers to be in the workshop rather than sitting in front of a computer.

Advantages:

- Interaktives PDF-Konfigurationsformular

- Sneaker- und Sportform zur Auswahl

- Fersenmulde in 2, 3, 5 mm Vorfußstärke

- TPU schwarz, Einlagenkörper 35°/Weichbettungen 25° Shore A

- Alle Pelottenformen mit individuellen Höhenabstufungen

- Optional leichter Toe bridge

→ Full customisation – design directly on the scan or pedography:

For digitally savvy engineers who want 100% control but don't need to be CAD professionals. A fully customised insole in just a few clicks: design the shape, function and material composition to fit perfectly. Ideal for businesses that want to integrate 3D treatments professionally and digitally – with maximum flexibility and minimum effort.

- Use the CAD Easycad Basic Module

- 7 insole shapes – from narrow to comfortable

- TPU white, Shore hardness freely selectable

incl. smooth transitions - Heel cup, inner/outer elevations (also rear foot only), heel mould

- Intuitive operation – can also be used directly in customer meetings

- Optional centralised production or

printing on your own printer

Which target group

would you like to reach?

Everyday life

For patients with everyday complaints such as foot, knee or back pain

Treatment goals:

We recommend

Diabetes

For patients with diabetic foot syndrome

Treatment goals:

We recommend

Would you like to invest

or try it out first?

Which solution is right for you?

Whether you are a beginner or an experienced producer - with our flexible solutions, you will find the perfect strategy for your digital insole production. Get advice and step into the digital future of 3D printing.

3D printing centralised production

3 ways to order:

- Order prefabricated models in the web shop

- Configure insoles using the PDF order form

- Design inserts in EASYCAD

Printing with GP Mike

Do you have further questions?

We will be happy to advise you on choosing the right hardware for your company or put together an individual offer for you.

3D-printed insoles

3D-printed orthoses

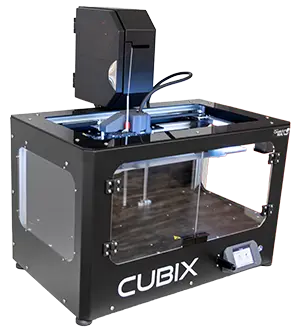

Take control: master your production with in-house manufacturing

Become independent with the GP Mike 3D inlay printer:

Basics and technology

1. exceptional adaptability: FFF enables a high degree of customisation in interlining production. By customising the settings and using different filament types, you as our partner can create insoles that meet the specific contours and flexibility requirements of individual users. This customisability ensures that each insole provides optimal support and comfort, tailored to the needs of the wearer.

2. cost efficiency: FFF equipment usually requires a lower initial investment compared to other 3D printing technologies such as SLS. The materials used in FFF, such as PLA, ABS and TPU, are not only inexpensive but also readily available, which lowers production costs. This makes FFF an excellent choice for orthopaedic practices looking to integrate in-house manufacturing.

3. speed and accessibility: FFF printers are known for their speed and ease of use, making them ideal for clinical environments. They enable fast production cycles, meaning orthopaedic clinics can produce insoles on demand, reducing waiting times for patients and streamlining the treatment process.

4. wide selection of materials: The range of materials compatible with FFF technology is constantly expanding, including options that are specifically suitable for medical use. Materials such as TPU provide the necessary flexibility and durability for orthopaedic insoles and ensure comfort and longevity in use.

By integrating Springer's FFF 3D printing into their production processes, orthopaedic specialists can not only improve the quality and effectiveness of their insoles, but also bring innovation and efficiency to their operations. FFF opens up new possibilities for patient care and makes personalised orthopaedic solutions more accessible.